![]()

The Audax body shell was used for ten years of Hillman Minx Series cars. Like the MGB, this shell was a first attempt at unibody construction and was therefore overbuilt. Frame rails were used for the front section extending from the front jacking points to the floorpan transition point separating the front and rear seat areas. At this transition point, the front frame connected to a cross member joining the outer sills. The rear frame section began at the front of the rear seat and extended to the rear jacking points. This design allowed for the deepset floor section in the rear seat area, giving more headroom to the rear seat passengers. The structural result transferred support to the outer sills. These sills were comprised of three parts: a outer sill panel making the "skin" wraping up into the door openings, a center sill panel section embossed to make it stiffer, and the innermost sill which was integral with the floorpan. The three sections came together at the bottom forming a single unit. Unlike American design used with the Chevy II and Nova cars made by GM, and the Falcon made by Ford, the Hillman front fenders were spot welded on, adding rigidity and strength to an already strong design. Unlike present day cars, the first Unibody designs were not made to "crush" on impact in the case of an accident, and the sheet metal used in Audax bodies was thick gauge. |

|

| SOME CAUSES FOR PREMATURE RUST FORMATION: | |

|

The Hillman Minx "Audax" Design Body Shell |

| The Series Minx "Sag" Explained | |

|

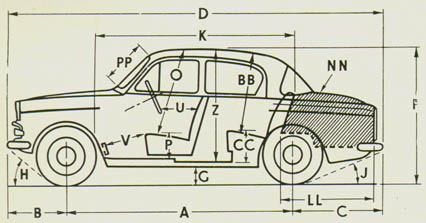

Over the years I have always wondered why all the Series Minx cars sag in the back - making the car appear tail heavy. The first thing that came to mind was that the rear leaf springs were weak - but are actually quite over-engineered in appearance for such a small car. Then I came across a rare booklet only given to Rootes Dealers to aid salesmen to become knowledgeable about the cars in order to sell them more professionally, (Something current dealers could profit from doing!). The photo at left is from the brochure, and depicts the Series Minx as DESIGNED with a lower posture at the rear wheels. The "G" point, which is given as the amount of ground clearance is taken at the middle point, which is an average. This makes the front of the car slightly higher, and the back of the car slightly lower than the actual clearance figure quoted in the brochures. An interesting bit of trivia, indeed, but I still think it would make the car look less "laden" if it were absolutely level all around. Guess we'll all have to live with the "sag". |

Email Webmaster with comments